Experiments offer fast and convincing answers which can be used for internal purposes or for external licensing and approval procedures. The HYKA facilities at KIT Hydrogen Safety Center are qualified and approved for a wide range of reactive gas dispersion and combustion experiments. The HYKA facilities offer new and unique experimental possibilities for safety researches in Europe.

They can be used for:

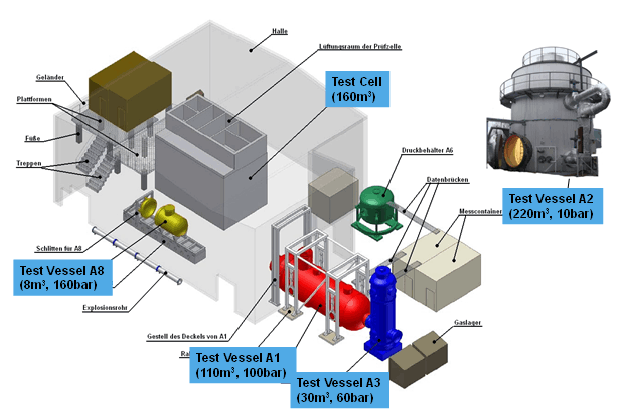

HYKA at KIT Hydrogen Safety Center including various test vessels, tubes and chambers with working pressure up to 160 bars.

used to study combustion processes in hydrogen-air mixtures. Especially quenching, flame acceleration and deflagration-to-detonation-transition (DDT).

A1: D = 3.4 m, L = 12 m, Volume = 105 m³

A3: D = 2.5 m, H = 8 m, Volume= 33 m³

Pressure: A1: < 100 bar; A3: < 60 bar

Experiments: turbulent combustion and detonations, vented explosions, hydrogen distribution, integrity of mechanical structures under high pressure load, natural convection ...

Projects (examples):

LACOMECO (2008-2011): Flame behavior of H2 / O2 / N2 mixtures with vertical concentration gradients with low to high geometrical congestion

GRS-Project (2008-2016): flat layer flame acceleration experiments for development of more robust and general criteria for flame acceleration.

H2FC (2011-2015): offered for transnational access

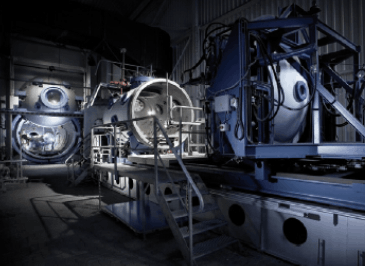

Dimension: D = 1.8 m, L = 3.7 m, Volume = 8.8 m³

Pressure: < 120 bar (static)

Experiments: studies on gas combustion and detonations, vented explosions, hydraulic and pneumatic

equipment explosions, integrity / fracture of mechanical structures under high pressure load, blast vessels, tests in vacuum, pressurized gas atmosphere or pressurized water.

Projects (examples):

FUSION (2007-2011): Ignition behavior of hydrogen rich mixtures under sub-atmospheric pressure

Industry (2011-2013): Large series of blast behavior, missile formation of Type 3 and Type 4 vessels

filled with H2 up to 700 bar

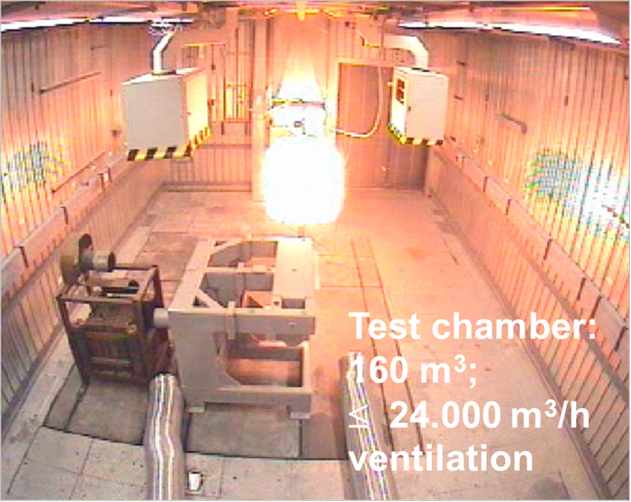

Dimension: 8.53 x 5.5 x 3.3 m, Volume = 160 m³

Pressure: < 10 bar (static)

Experiments: studies on distribution, ventilation system,

vented combustion and detonation of H2 (< 20 g in case of detonation), testing of automotive systems.

Projects (examples):

ICEFUEL (2006-2009): Release from LH2 hydrogen pipeline. Cryogenic multiphase jet behaviour, ignition and flame properties.

HyIndoor (2011-2015): EC Project for indoor use of hydrogen – vented explosions. Investigate venting strategies

Dimension: D = 6.0 m, H = 9.0 m, Volume = 220 m³

Pressure: < 10 bar (static)

Experiments: studies on fire, gas combustion

and detonations, vented explosions, hydraulic

and pneumatic equipment, integrity and

fracture of mechanical structures under excessive

pressure load, blast.

Projects (examples):

LACOMECO (2008-2011): flame instabilities of large lean inventories with vertical mixing gradient.

CryoSys (2009-2011): fire testing of automotive cryo-compressed storage vessels.

POFII (2012-2013): 2D flame instabilities in flat layers.